CAPABILITIES

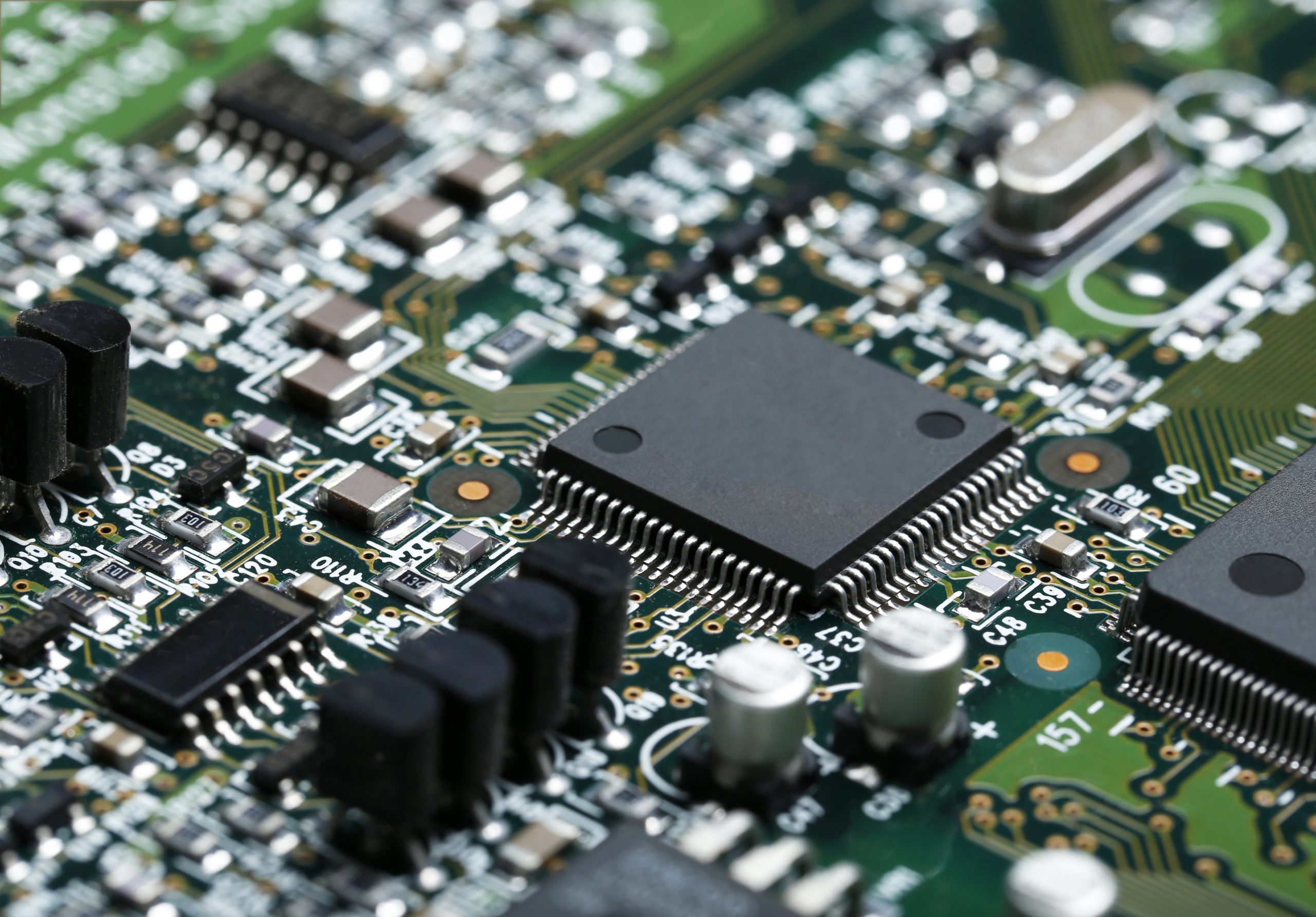

Exponent Assembly’s state of the art machinery and experienced production staff provides the capabilities to manufacture electronic printed circuit board assemblies, from complex surface mount technology to through-hole and Mixed-Technology. We use unleaded (RoHS) and leaded solder. All while maintaining safe and traceable sourcing, an ISO 9001:2015 quality management system, and IPC-A-610 quality control.

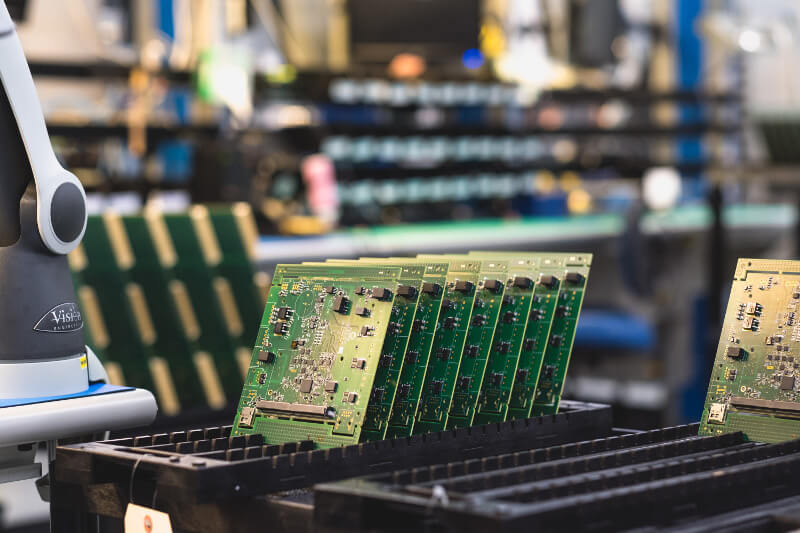

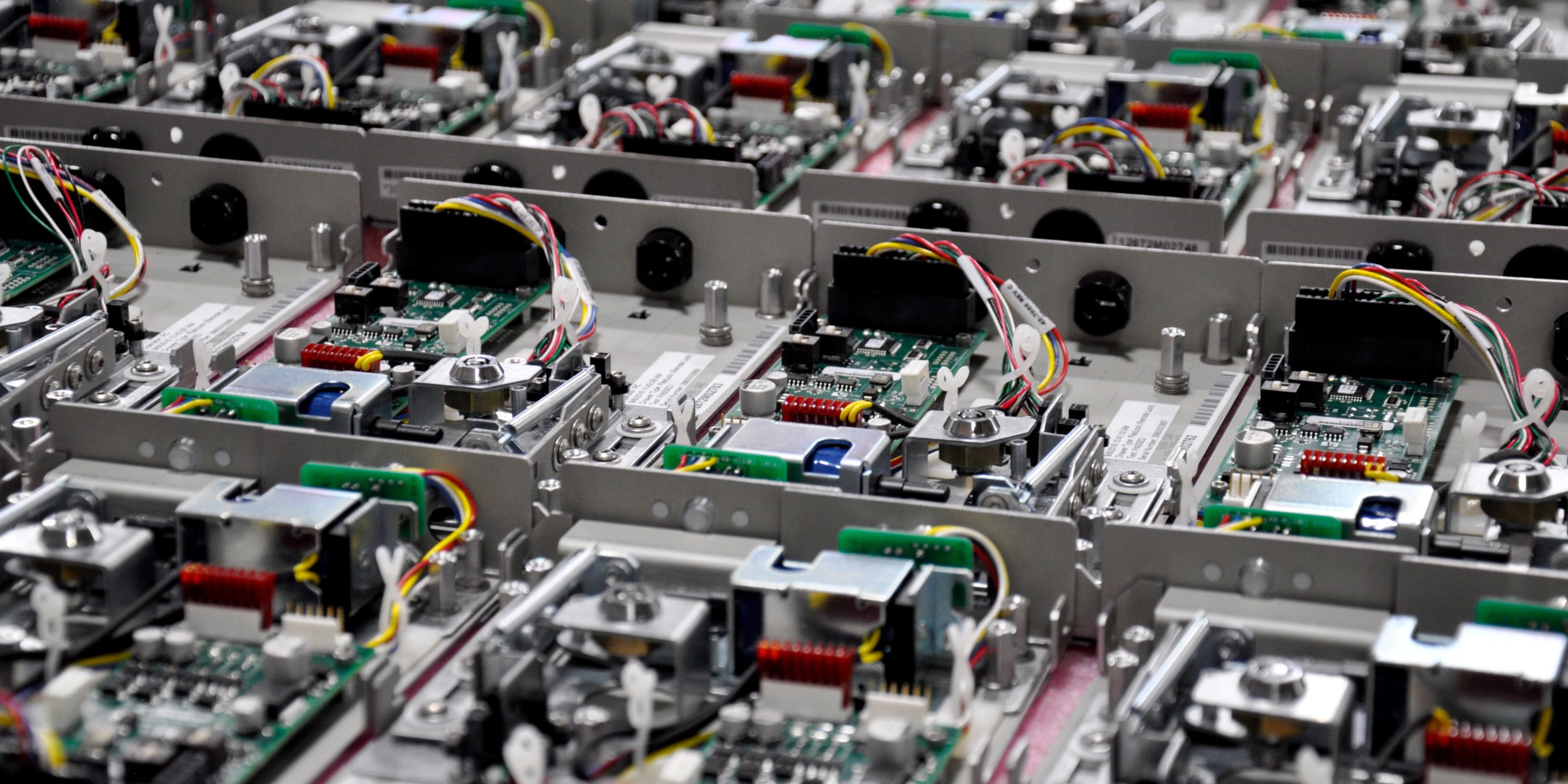

Volume Printed Circuit Board Assembly

Exponent Assembly is committed to dependable and scheduled deliveries, no matter your companies volume production needs. From medium to large quantities, Exponent Assembly can fit your PCB assembly demands.

Prototyping Printed Circuit Board Assembly

Prototyping costs can be costly and time consuming. Exponent Assembly offers quick turnaround times while still maintaining 100% quality and traceability.

Surface Mount Technology

Our pick and place machines can place 30,000 parts per hour, precisely placing 0201 passive to micro ball grid array components. Our state of the art machinery can accommodate:

- Double-sided, multi-layered, or high-density PCB assembly

- QFP’s, QFN’s, CSP’s, LCC’s

- BGA placement

- LEDs

- Melfs, Electrolytic Capacitors, Shields

- Odd-forms and Connectors

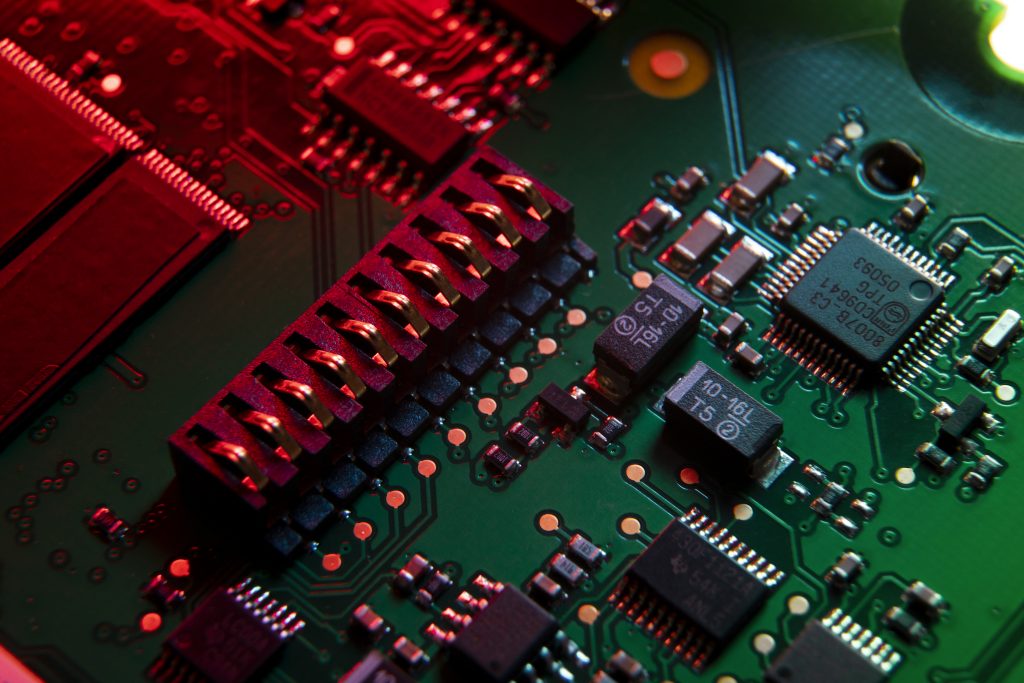

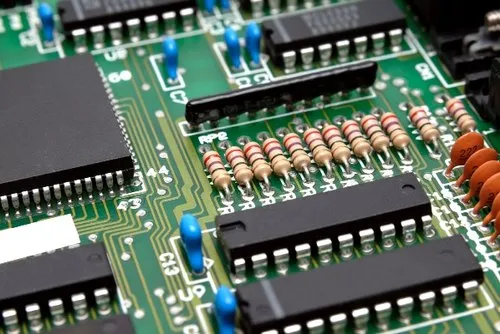

Through-Hole Technology

With our Selective soldering machine, wave soldering machine and experienced hand solderers on staff, Exponent Assembly can handle any thru-hole project. Between automated flux sprayers and two preheating zones to properly activate flux we achieve optimal solder wetting.

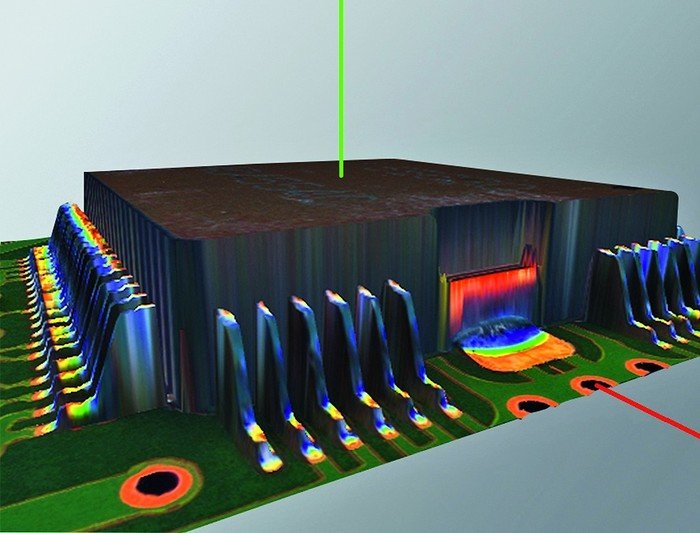

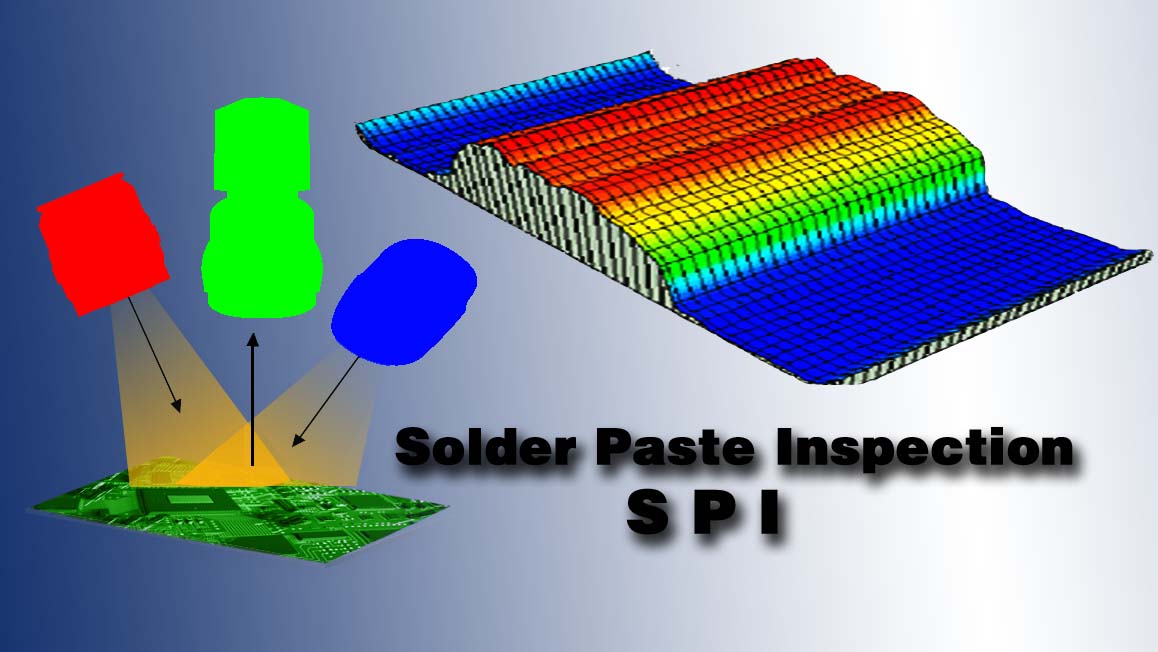

Inspection Capabilities

We use 2D and 3D capable technology to ensure quality of printed circuit board assemblies manufactured. These equipment enables us to 2D and 3D inspection of solder paste, solder joints, component placement, etc.

- 3D Solder Paste inspection to measure solder paste volume and footprint

- 2D and 3D capable Automated Optical Inspection to inspect solder joints and component placement

- IPC-A-610 certified staff

Electromechanical Assembly

Exponent Assembly provides a full-service assembly shop, from PCB assembly to the finished product. Mechanical assembly capabilities include:

- Prototype and production builds of mechanical assemblies and sub-assemblies

- Parts assembled into molds or fixtures using glue, snaps, or screws

- Testing of each assembly/sub-assembly

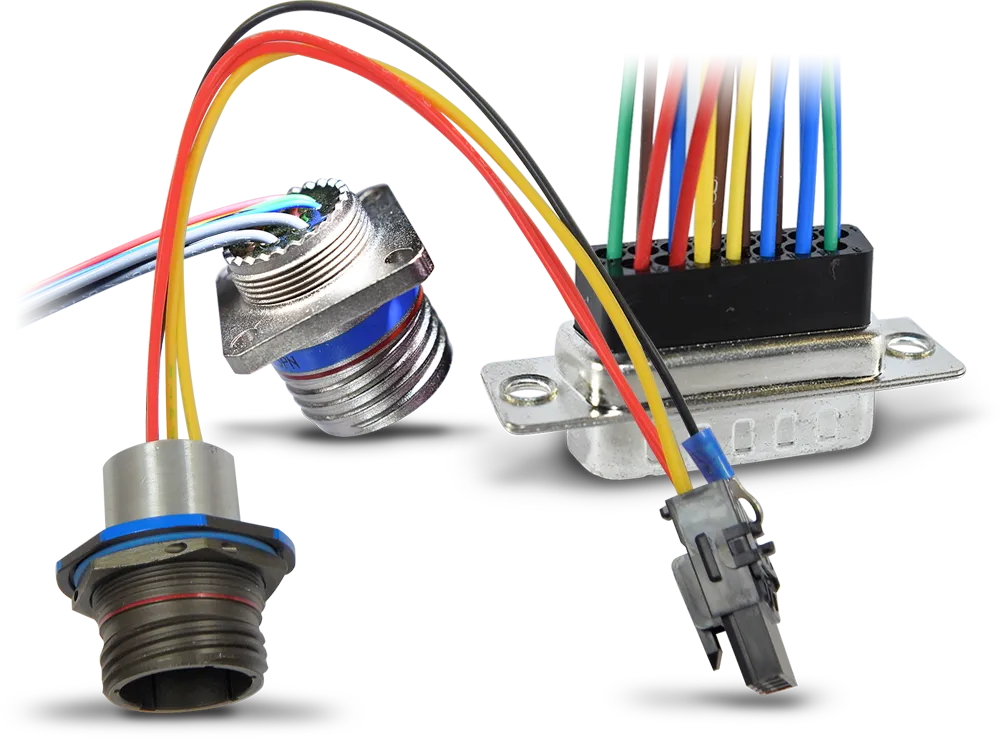

Wire harness and cable assembly

Exponent Assembly offers Cable and Wire harness with various cables and connector types to meet your requirements. We have a diverse team of engineers and assemblers to help build custom cables that are engineered for your specific challenges.